GIRAD

IGRAF

GIRAD

Main features:

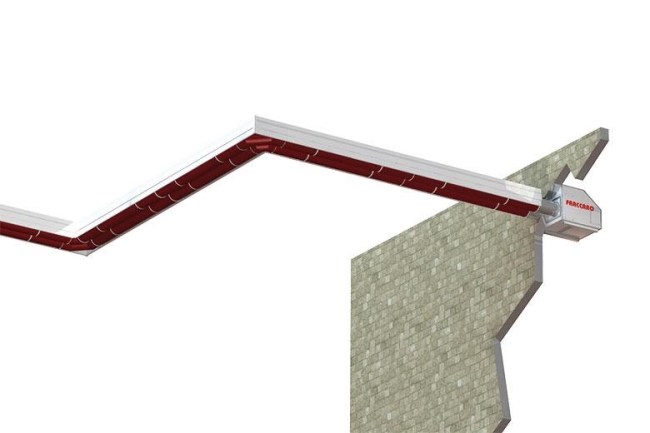

The installation of the Radiant Modules consists of a patented heat generator, a single or double-pipe radiant circuit and a thermoregulation digital device.

The radiant circuit is a closed ring having go and return tubes working in vacuum condition. The gas or gas-oil burner produces a carrying fluid (a mixture of air and burned gases) which circulates at high speed inside the tubes of the radiant circuit. The tubes reach a superficial temperature from 100°C to 300°C (according to the requirements) producing the radiant energy necessary to provide the required environmental comfort.

The pipes are in aluminized steel, treated with special silicone paint and insulated with fiberglass panels on three sides. The radiant circuits are pre-assembled and tested in our factory; their installation on site turns out to be very easy also thanks to their flanged joints.

KEY BENEFITS

COMBUSTION EFFICIENCY up to 95% or 107% in models equipped with condensing unit*.

ECOMIX BURNER air-stream gas burner with VENTURI tubes working in constant proportional modulation.

ECOSAVING DEVICE that controls the chimney lock-gate and allows to keep optimal combustion efficiency at any power level**.

PRE-ASSEMBLED MODULES They are produced and assembled in our factory to make the installation job easier and quicker***.

THERMAL POWER up to 300kW and circuit lenght up to 160m.

DIGITAL THERMAL CONTROL allows you to operate the system from remote stations and get remote assistance service (optional).

MINIMUM MAINTENANCE through the reliability of all components and exacting tests complying with European standards both in the assembly line and in the in-house laboratory. All this ensures high reliability and long-term safety.

OTHER ADVANTAGES

NO AIR STRATIFICATION or rather no warm air shall accumulate in the high areas of the room being heated; on the contrary, as far as the air goes upwards, the air temperature itself decreases.

EXCELLENT THERMAL EMISSION generated by the large radiating surface with high emissivity.

HEALTHIER AND CLEANER AIR There are no convective motions and consequent raise of dust, keeping the air healthy and clean.

COMFORT TO CURRENT STANDARDS Our long experience stretching back over thirty years of activity, added to our participation in work groups specifying standards for products, make Fraccaro an ideal partner in this specific sector of heating technology.

EASY, RAPID INSTALLATION thanks to an easy assembling procedure and installation on the ceiling with chains.

NO FLOOR OR WALL SPACE IS REQUIRED as our GIRAD Radiant modules are installed on the ceiling.

NO DANGER OF FROST as the lack of carrying fluids, such as hot water or steam, makes it possible to shut down the system for long periods without any unfortunate consequences.

UNIFORMITY OF TEMPERATURE the heat produced through radiation by our Radiant Modules creates uniform temperature horizontally through the building, better than with any type of traditional heating.

HIGHLY ECOLOGICAL as it allows for fuel saving, with great combustion performance and very low emissions of pollutants.

MODULAR DESIGN i.e. for large surfaces more than one units are to be installed.

MODULATING OPERATION of generators, so as to control the radiating heat emission according to the external temperature.

NO AIR STRATIFICATION or rather no warm air shall accumulate in the high areas of the room being heated; on the contrary, as far as the air goes upwards, the air temperature itself decreases.

RAPID WARM-UP due to lack of intermediate fluids requiring heating.

CONFORM TO CURRENT STANDARDS Our long experience stretching back over thirty years of activity, added to our participation in work groups specifying standards for products, make Fraccaro an ideal partner in this specific sector of heating technology.

PRE-ASSEMBLED MODULES

The radiant module is realized with a supporting frame in zinc-coated steel. The frame supports one or two pipes in aluminized steel treated with silicone paint and having insulating fiberglass panels on three sides. The pre-assembled modules in 1.5, 3 and 6-meter length allow a very flexible application of the circuits whose length and shape can vary according to the requirements of the building to be heated.

They are produced and pre-assembled in our factory to make the installation job easier and quicker. Thanks to the special chain connection to the supporting frame, the pipes are free to move while heating or cooling assuring a very long lasting to our modules.

MODULE CONNECTION

The flanged cone-shape joints ensure perfect pipe tightness; during the installation they avoid problems coming from the traditional connections with silicone, gaskets or other adhesive components.

The bayonet joint of the radiant modules ensure the perfect tightness of the radiant circuit.

IGRAF

Main features:

Heat exchanger and burners of ovens for drying process and heating of liquids.

Possible applications:

Process liquid Heating

Heating and drying of various materials

Drying plants

Painting ovens

Food baking

ADVANTAGES

Reliability

Low operation costs

Easy use and maintenance

Excellent process control

INNOVATION and QUALITY

Make-up air suction burners with stainless steel box

High combustion efficiency

Multiventuri combustion unit

Burners with thermal power from 10 to 300kW

Two-stage operation

Full operation in very short time

No thermal unit are required

Compact

Low operation costs

Easy installation and maintenance

Eco friendly

Low CO and NOX emissions

Reliable and durable products

Efficiency above 90%

Thermal power 40-300kW