INFRARED (IR) BURNER

INFRACAT

BOOSTERCAT

RADIANT HIGH TEMPERATURE

INFRARED (IR) BURNER

Main features:

We supply infrared catalytic gas heaters and radiant systems manufactured by INFRAGAS, suitable for surface thermal treatments e.g. paint coating drying, pre-heating, dehydration, drying of different substrates.

High technology combined with extremely low management costs, the easy operation and working efficiency make Infragas heaters a flexible heat source. Flameless catalytic heaters infrared radiant systems are completely safe and environment friendly.

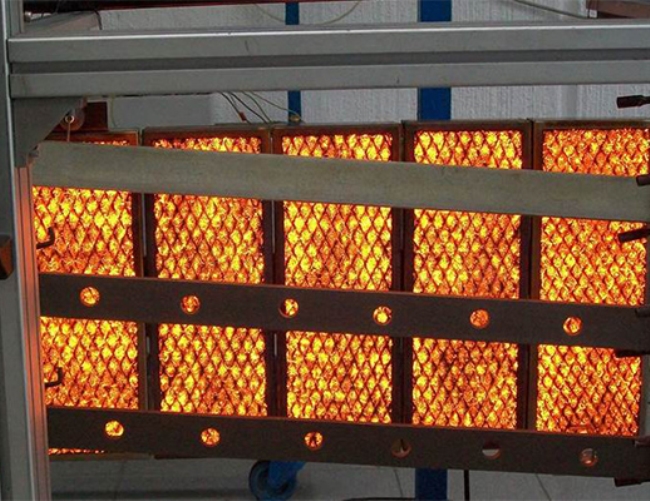

INFRACAT

Main features:

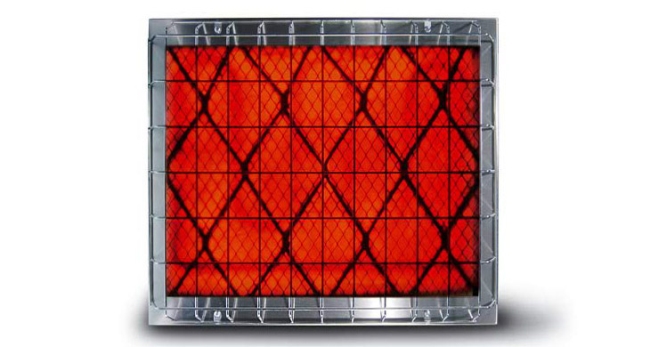

Infrared catalytic panels named INFRACAT®, whose trade-name is the combination of INFRared energy and CATalytic technology, are characterized by surface temperature capable of being modulated from 180°C (365°F) to 550°C (1022°F).

INFRACAT panels are available in the following versions:

standard with “K” type thermocouple for modular applications in ovens

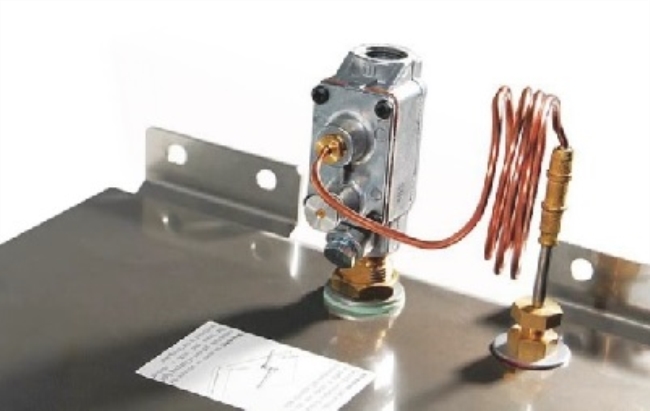

integrated “shut-off” manual valve or thermostatic manual valve in case of panels used as independent units for heating or industrial thermal treatments.

According to the size, power changes from 0,4 kW (344 kcal/h) up to 17 kW (14617 kcal/h), as they have been designed to develop a specific power of 20kW/m2.

INFRACAT panels certifications:

CSA CERTIFICATION

Canadian Standard Association – Class 1, Division 1&2, Group D – Explosion Proof products;

FM CERTIFICATION

Factory Mutual Approvals for use in classified areas Class 1, Division 2, Group D – Explosion Proof products;

ATEX CERTIFICATION

CE marking in conformity with the Directive 94/9/EC for use in potentially explosive atmospheres, Group II, Category 2 G – Explosion Proof products;

GOST CERTIFICATION

for Russian Federation;

UKR-SEPRO CERTIFICATION

for Ukraine.

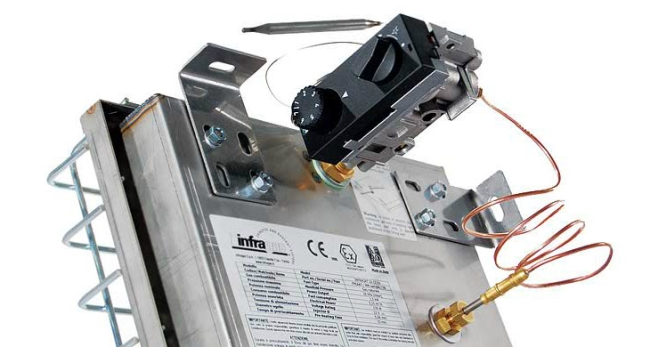

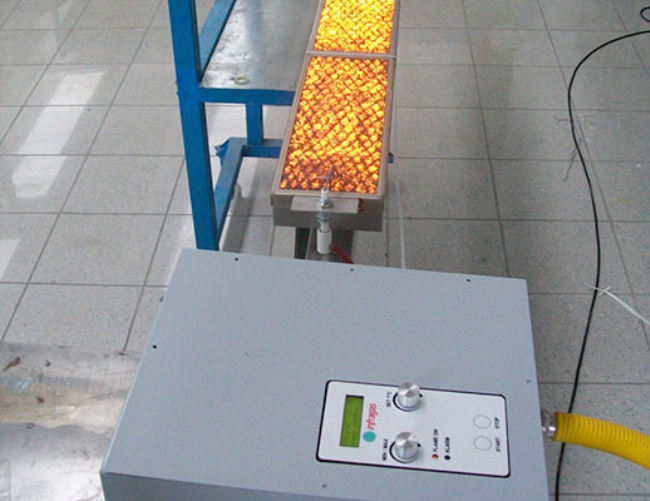

BOOSTERCAT

Main features:

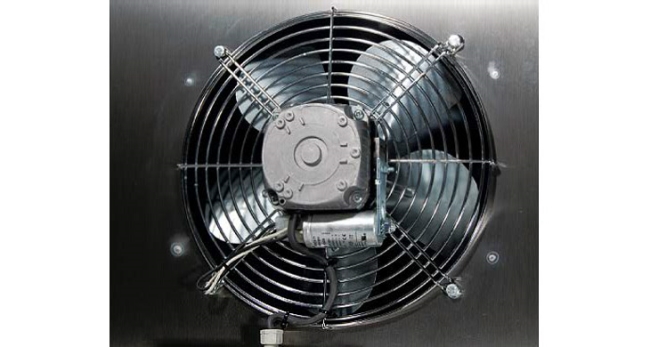

Infragas manufactures infrared vented catalytic panels named BOOSTERCAT®, whose registered trade-mark synthesizes catalytic technology empowered by the action of an integrated ventilation system or a forced air system through canalizations positioned on the back of the heater.

BOOSTERCAT surface temperature is capable of being modulated in a range from 180°C (365°F) to 650°C (1202°F) and, according to the specific size, range from a power of 6kW (5143 kcal/h) up to 25kW (21500 kcal/h).

Boostercat certifications:

ATEX CERTIFICATION

CE marking in conformity with the Directive 94/9/EC for use in potentially explosive atmospheres, Group II, Category 2 G – Explosion Proof products;

GOST CERTIFICATION

for Russian Federation;

UKR-SEPRO CERTIFICATION

for Ukraine.

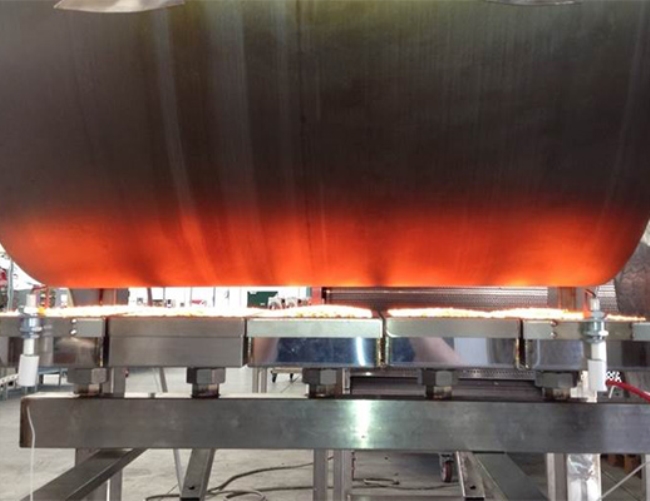

RADIANT HIGH TEMPERATURE

Main features:

INFRAGAS radiant heaters RHT are infrared systems able to reach a surface temperature up to 950°C.

RHT burners are a safe and reliable source of heat generated by a gas combustion (Natural Gas or Propane) and transmitted through infrared rays in short wavelength. The infrared energy emitted by the RHT radiant surface is absorbed by the exposed materials fast and uniformly. They are specific for thermal processes that require high temperatures or rapid curing time.

Frame and body of the RHT are totally made with specific stainless steel for high temperature working conditions. Each burner is equipped with a pre-mix system with a calibrated mixture of air/gas.

The RHT operates in a range of power from 100% to 50%.

With reference to the environment respect, it is important to take into consideration that the surface microflame combustion with the metal fibre burner emits extremely low levels of NOx, CO and unburned.

Infragas RHT burners are manufactured in conformity with the requirements of the International Standard ISO 9001 and they are checked and tested individually before each dispatch. Moreover, they are CE certified according to the European Directive EN 419-1: 2009 and EN 437:2003+A1:2009.

RHT=

HIGH TEMPERATURE

EASY TO INSTALL

QUICK START-UP

POWER MODULATION

UNIFORM THERMAL TREATMENTS

FLEXIBILITY

INDIPENDENT SYSTEM

ENVIRONMENT RESPECT

SAFETY